Nazdar’s Terry Kimrey and Laura Patriquin explain the differences between cured and dry ink.

You’re rushing to get that new print order done for a crucial customer. You’ve run the ink, you have all the prints ready to go. As soon as the 10,000th print comes off the line, you quickly run one final rub test to ensure that they will adequately resist the chemical solvent they’ll be coming into contact with as a part of end-use.

Panic sets in – the ink comes off. Previous testing showed the ink to have good chemical resistance, so what happened? Did the ink go bad? Are all these prints wasted now?

An Important Distinction

Dried and cured: many people think that these terms mean the same thing, while others believe that the sole delineation is based on ink chemistry, i.e. solvent or UV-curing. While the two are certainly related, there is more to the story of cured versus dried ink films.

When an ink is printed either by screen, inkjet, roll-coater or other methods, the initial point where the ink becomes hard and does not mar when touched is when it is considered dried. This is true of all ink chemistry types (solvent, water-based, UV, etc). Where some confusion comes in is when discussing UV or UV-LED ink. Because a chemical reaction takes place in the ink when exposed to ultraviolet light, this process is known as “curing” the ink. As we’ll review, though, this initial curing process does not mean that the ink is immediately fully cured.

Initially cured inks often do not perform to their full capability, potentially failing tests such as adhesion or chemical resistance.

Solvent and Water-Based Inks

Solvent and water-based inks typically dry by evaporation – the solvent or water evaporates out of the ink, leaving a dried ink film. The dried ink film will be non-tacky to the touch and resist marring. A common test for dryness is the thumb twist: a thumb is placed on the ink film and twisted with medium pressure. If ink does not displace, it is an indication that the film is dry.

In some cases, however, the drying process is only the start of the finished ink film. While a film may initially be dry to the touch, inks in which a chemical reaction takes place over time are known as reactive inks.

This longer-term hardening of the ink is sometimes referred to as the curing stage – though the terminology is similar, this is different than the curing referred to when UV ink is exposed to ultraviolet light.

UV and UV-LED Inks

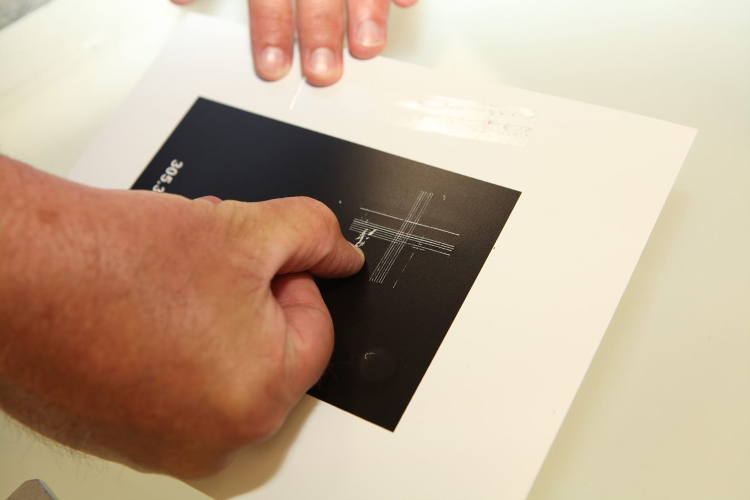

Instead of evaporation, UV and UV-LED inks become dry due to a chemical reaction in the ink. When the print is passed under ultraviolet light, molecules in the ink – known as photoinitiators – start a reaction that causes other molecules – monomers and oligomers – to “grab onto” one another and produce a dry-to-the-touch ink film after the print exits the unit and cools down. As with solvent or water-based inks, the thumb twist test should be performed on prints created with UV inks to determine if the ink is curing properly.

While a UV ink may be touch-dry, complete curing is critical to a UV ink’s performance – this is often a process that occurs over a period of time after initial curing. Inks will often not perform correctly until they are fully cured. Take our example at the beginning of this article – ink that needs to resist a chemical solvent, ensuring that the printed graphic will not erode upon coming into contact with it. As in this case, an initially cured UV ink may fail a resistance test, while a fully cured ink is much more likely to pass.

Determining when an ink is fully cured can be tricky. While ink manufacturers usually provide a general recommendation, a wide range of factors can affect cure time. These factors can include environment, processing, equipment, and additives used in the ink. Heating a print may reduce cure time but risk making the ink brittle, while additives such as thinners, catalysts, and adhesion promoters can increase cure time.

As a printer, all these factors must be considered in determining when a print is ready to perform to its maximum capability.

UV inks become dry to the touch through a process known as curing.

Recap

So, when is it correct to use the terms dried or cured? Dry-to-the-touch, solvent and water-based inks can generally be considered “dried.” However, though UV and UV-LED inks exit the reactor touch-dry as well, using the term “cured” is a more accurate description. It may also be helpful to include a qualifier, such as initially cured, as the dry ink may still be undergoing chemical reactions; it is not until the ink is fully cured that it is able to perform to its best capability.

In our original example, the prints may have only needed more time – once fully cured, the ink would perform as intended with all its chemical-resistant properties, leaving you with a happy customer (and considerably less panic for you, as a printer). Simply put, while an ink can be both, an ink that feels dry may not necessarily be fully cured, and understanding the distinction between the two is essential to maximizing the performance of your ink and your entire print process.

Have questions on dried or cured ink films? The Nazdar InkAnswers technical team can answer these and other print-related questions at InkAnswers@nazdar.com.

For more information on Nazdar and its comprehensive range of ink solutions, please visit www.nazdar.com.